Water jet machine | Why is the "water jet" so powerful when it is easy to cut through the steel plate?

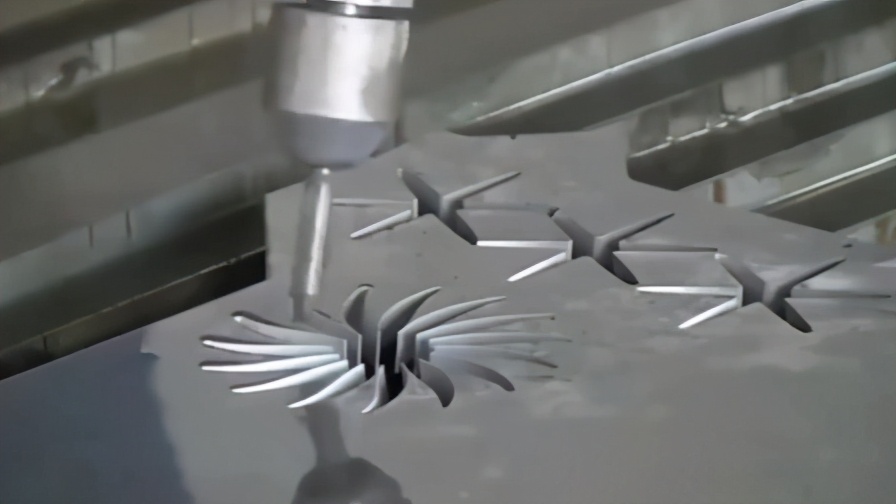

Water jet machine

Water can cut everything, because water can be a knife, that is, "water jet", whose real name is high-pressure water jet cutting technology. This technology was originally invented by the Americans and was applied to the field of aerospace technology. But at that time, the water jet was a new type of tool, without the technological sense of electronic products and the metallic sense of mechanical products, so it was not taken seriously by them at that time.The biggest feature of the water jet is the one-time cutting of any curve of any object. Moreover, the water jet is cold cutting, which will not cause chemical and physical reactions to the material, nor will it produce toxic substances, so the water jet is favored by everyone. After continuous improvement, the speed, thickness and precision of water jet cutting have been greatly improved. Now water jets are widely used in ceramics, metals, glass, wood and composite materials, and also play an active role in aerospace, medical, blasting, electric power, petrochemical, marine and construction.

Compared with other cutting methods, what are the advantages of water jet?

The first is laser cutting. Laser cutting is very fast and precise, but compared to water jets, laser cutting is too expensive. Moreover, high temperature is generated during laser cutting. When cutting aluminum, copper and thicker steel plates, the effect of laser cutting is not good, and it is likely to burn the material. Compared with the two, the waterjet has a smaller investment, a wider cutting range, and the speed is not bad. The most important thing is that it is not destructive.

Look again at plasma cutting. Plasma cutting is not as good as laser cutting. It not only generates heat, but also has low precision. The surface after cutting is difficult to perform secondary processing, which is equivalent to a piece of "waste". Compared with the two, "water cutting" will not deform the material, the cutting quality is better, and it is easy to carry out secondary processing.

There are other punching and shearing process cutting, flame cutting, etc., which also have strong limitations. In contrast, "water cutting" has become the leader of the cutting world.