Features and advantages of water jet cutting machine

Compared with the traditional "hot" cutting process, the ultra-high pressure water jet cutting machine uses water as the cutting medium, which is a "cold" cutting process. It has the following functions and advantages:

1. No thermal deformation during cutting, avoiding physical and chemical changes of materials;

2. It is widely adapted to the cutting process of various materials and has the reputation of "universal cutting machine";

3. The cut is smooth and flat without burrs, and generally does not need to be reprocessed;

4. Operated by the numerical control system, with high cutting precision;

5. The cutting seam is less than 1.2mm, which is convenient for nesting cutting and saving materials;

6. The processing process will not produce waste that pollutes the environment.

CNC waterjet is ideal or the only processing method for materials that are difficult to cut by other methods, such as Kevler, titanium alloy and various composite materials.

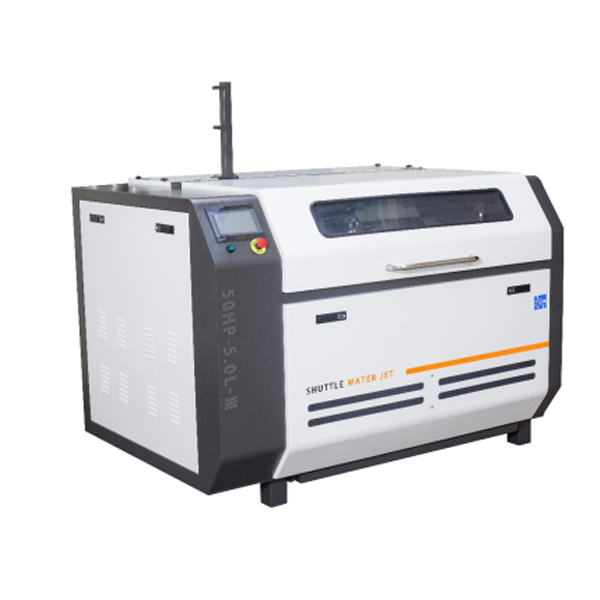

water jet cutting machine

1. No thermal deformation during cutting, avoiding physical and chemical changes of materials;

2. It is widely adapted to the cutting process of various materials and has the reputation of "universal cutting machine";

3. The cut is smooth and flat without burrs, and generally does not need to be reprocessed;

4. Operated by the numerical control system, with high cutting precision;

5. The cutting seam is less than 1.2mm, which is convenient for nesting cutting and saving materials;

6. The processing process will not produce waste that pollutes the environment.

CNC waterjet is ideal or the only processing method for materials that are difficult to cut by other methods, such as Kevler, titanium alloy and various composite materials.

water jet cutting machine